MUNICIPAL BUDGET EDUCATIONAL INSTITUTION

ADDITIONAL EDUCATION

"CREATIVITY CENTER

ZAVODSKOY DISTRICT" OF THE CITY OF KEMEROVO

Straw inlay

Educational activities: Straw applique

Children's age: 11-12 years old

Full name teacher: Suslyakova Lidiya Yakovlevna

Department: Arts and crafts

Compiled by: teacher

Suslyakova Lidiya Yakovlevna

Kemerovo 2016

Lesson summary on the topic:

"Straw inlay"

Target: - students’ mastery of ornaments, methods of making inlays, technologies for making inlays “marquetry” and “intarsia”.

Tasks:

Learn how to make a sketch of an ornament to design a rectangular product in the “inlay” style;

Develop skills in working with straws, imagination, and aesthetic taste;

Instill responsibility for the work performed.

Visibility:

Cutting boards inlaid with straws;

Dolls in inlaid clothes;

Encrusted eggs and wooden spoons;

Samples of ornaments in a rectangle.

Equipment:

Candy box;

Prepared format;

PVA glue;

Tassels;

Scissors;

Napkin;

Cardboard;

Glued strips of straw.

Type of activity : combined.

Basic concepts: inlay, marquetry, intarsia.

Lesson progress:

Teacher's actionsStudent Actions

I. Organizational moment.

Greetings;

Checking readiness for class;

Reporting the topic of the lesson, setting goals.

What new will we learn in class?

What will we learn?

II. TB instruction.

Safety rules when working with scissors.

(Appendix 1)

Students repeat the rules

III. Presentation of new material .

Do you know what holiday is coming soon?

Yes, this is the holiday of Holy Easter and now the Holy Week of preparation for this holiday is taking place. The custom of painting and decorating eggs began from the moment when Mary Magdalene (a holy follower of Christ) told Emperor Tiberius the news of the resurrection of Christ and it was at that moment that she presented him with an egg as a gift. But the emperor did not believe this and said that the egg would rather change color than the dead person would be resurrected. After these words, the egg turned red. Since then, a painted egg has been considered a symbol of eternal life, and painting and decorating eggs for Easter has become a tradition of many peoples.

I will show you samples of eggs encrusted with straws (Appendix 2)

You already know that the art of straw mosaics originated in Belarus and more recently, altar doors made in the 18th century were discovered in 2 abandoned churches in the Brest region of Belarus. So these truly royal doors were inlaid with straw

The first to try to glue the simplest pattern out of pieces of straw were cabinet makers who mastered the technique of mosaic finishing of wood.

Inlay – decorating products with patterns made from straw, pieces that are cut into the surface and differ from it in color or material.

Grooves were cut out on a wooden base, into which straws were then glued.

Inlay means to cut.

The modern technique of inlaying with straw differs from the ancient one in that its elements are not cut into a wooden base, but are glued to its surface and this is called applique.

Marquetry - the background is completely covered.

Intarsia - most of the base is open and serves as a background.

2. Types of ornament:

Geometric, floral, combined.

Display of samples of ornaments and works. (Appendix3)

Students call the holiday Holy Easter

IV. Consolidation of new material.

Frontal survey.

What types of applications do you know?

What is the name of the type of applique in which most of the background is open?

What are the types of ornaments?

Students answer:

Marquetry, intarsia.

Students answer: intarsia.

Students answer:

geometric, floral, combined.

V. Practical work.

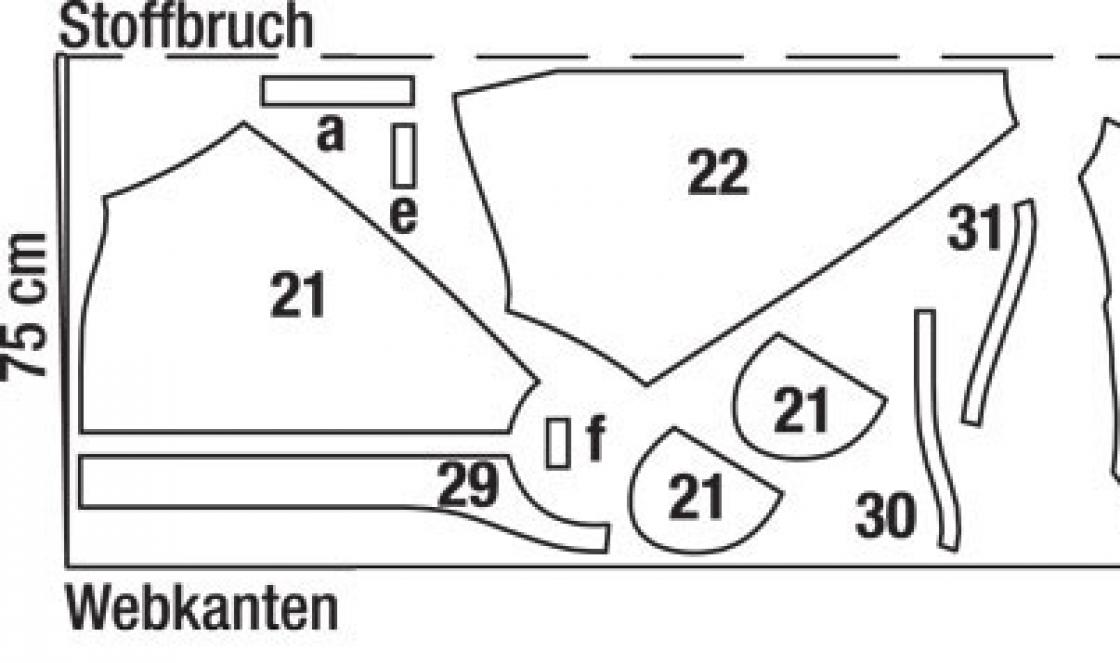

1. Drawing up a geometric pattern. Select an ornament from the technological map (Appendix 4).

2. Cutting out applique details. The straw is easily cut with scissors into rectangular pieces, squares, and diamonds. It is more difficult to cut triangles and pyramids out of it. It is almost impossible to use ornamental designs with elements of a circle, oval, or semicircle.

3. Gluing applique parts onto a strip of cardboard

Having chosen a design and marked it, begin to paste over the product, gradually cutting out the desired geometric shapes from the straw and gluing it to the desired places.

4. Self-control actions:

While performing work, monitor your posture;

The appliqué parts should be symmetrically located;

Apply the glue evenly, in moderate quantities, immediately after gluing.

Remove remaining glue with a napkin.

Pasting a product with a geometric pattern can only be good when it is done exactly according to the markings, the same shape and the same size.

Students choose an ornament from the technology map.

Cut out the parts and glue them onto a strip of cardboard.

VI. Summing up the lesson.

1. Cleaning workplaces.

2. Analysis of work.

3. Reflection (Appendix 5).

Island of Disappointment

Island of Bad Luck

Island of Misunderstanding

Island of Hope

Island good mood

Students cleaning workplace, put the remains of straw ribbons, tools, devices into boxes, analyze the work done and fill out a questionnaire.

Application

Island of Disappointment

Island of Bad Luck

Island of Misunderstanding

Island of Hope

Island of good mood

Appendix 1

Safety precautions when working with scissors

1. Store the scissors in the specified location and position.

2. When working, carefully monitor the cutting direction.

3. Do not use dull scissors or loose hinge joints.

4. Do not hold scissors with the blade facing up.

5. Do not leave scissors with open blades.

6. Don't cut with scissors as you go.

7. Do not approach your friend while working.

8. Pass the closed scissors rings forward.

9. As you work, hold the material with your left hand so that your fingers are away from the blade.

Straw inlay

In inlay, straw is used as a decorative material. First, a product is made from wood, then its surface is primed, painted, and then decorated with straws.

For inlay (application) use rye, oat, and meadow grass straw. It is harvested for future use during the period of milky-wax ripeness, in July - August: cut, dried for 2-3 days, spikelets, ring nodes and leaves are removed with scissors, then sorted by length, thickness, color and stored in a dry, dark place.

To give the stem more uniform shade, remove stains, grayishness, the straws are pre-bleached. To do this, prepare the following composition (g): water - 1 l; 15% hydrogen peroxide - 150; ammonia - 20; caustic soda - 40. The straw is immersed in a warm (not lower than 30-35°C) solution and kept in it under load for 10 minutes to 1.5 hours, stirring constantly. Then take it out and wash it at least twice in cold water, adding vinegar to the last water.

Straw can be bleached well with a solution of hydroperite (18 tablets per 3 liters of water). The straws are immersed in the solution and bleached over low heat for 1 hour, stirring constantly.

Colored straws are produced by dyeing with aniline fabric dyes. A little salt is added to the coloring solution to fix the paint, and vinegar essence is also added. To obtain the required tone, the following compositions are recommended (per 5 liters of water):

For light tone: 1-3 g dye; 7 g salt; 2 g vinegar essence;

- for medium tone: 3-6 g of dye; 12 g salt; 4 g vinegar essence;

- for dark tone: 6-10 g of dye; 15 g salt; 5 g vinegar essence;

- for black tone: 10-12 g of dye; 25 g salt; b d vinegar essence.

Before dyeing, the straw can be kept in a soda solution (1 tablespoon of soda per 2 liters of water) - then the shade will be more uniform.

The straws are loaded into a metal container with a hot dye solution, covered with a lid and boiled for 20-90 minutes, constantly stirring with a wooden stick. Take the straw out of the cooled solution, rinse it at least twice in cold water and place it in a vinegar solution for 10-15 minutes (2 tablespoons of vinegar essence per 5 liters of water) - this will fix the paint and it will not stick to your fingers while working. . Then the straw is placed on its end, when the water has drained, laid out in a thin layer and dried at room temperature for a day. Dry colored straws are stored in bundles in a dry place.

You can turn the straw brown by holding it under a hot iron or in a hot oven for a few minutes.

In addition to straw, to perform inlay, you need to prepare glue, nitro varnish, stain, nitro enamel, sandpaper, putty and other materials, which will be discussed later, as well as various tools and devices.

The main tool for performing inlay is a scalpel and a knife-cutter (jambs), sharpened at angles of 30, 45, 60°. You will also need semicircular chisels, punches for making curved elements, a penknife, pencil, brushes, ruler, square, compass, surface planer. Among the auxiliary accessories, it is necessary to have a glue boiler, a jar for varnish, a bath with a sponge soaked in water, abrasive bars for sharpening tools, and a press (weight) for gluing.

Before starting work, the straw is moistened with water to make it more pliable and less likely to break. Then, using a knife blade, cut the stem along the fibers and straighten it wooden block, running the knife from the inside and outside away from you at an angle of approximately 30°.

You can smooth the split straw onto the paper with a hot iron several times on both sides, thus obtaining a shiny straw ribbon. In this case, it is recommended to pre-steam the straws for 20-30 minutes before splitting.

A well-processed straw, after straightening, will fit into a ring.

The straws prepared in this way are sorted by shade.

The design for inlay is usually done in life size. Transfer to the surface to be decorated using copy paper with a sharpened pencil. Only the main lines are outlined, since small details only contaminate the base.

Inlaying with straws can be done on the ground or on the varnish.

Technique of inlaying on soil. Soil composition (g): wood glue - 400; water - 500; black dye - 8; glycerin - 40; detergent"Extra" - 8. The primer is applied in two thin layers with intermediate and final drying for 4 - 5 hours and carefully sanded along the grain with fine-grained sandpaper. When laying out the ornament, a strip of straw is held in the left hand, a scalpel in the right (Fig. 54, a). The soil under the straws at the place where they connect should be slightly moistened with water with the index finger of the right hand. Using a scalpel, cut off the required pattern element from the strip and carefully rub it onto the plane with the blunt end of a handle or a scalpel blade at an angle of 30°.

Rice. 54. Techniques for working with straw when inlaying (applique): a - cutting off the pattern element from the strip of straw; b - technique of working with a brush.

The finished inlaid surface is coated with nitro varnish at least twice, drying each layer well.

Technique of inlaying on varnish. The surface to be decorated is carefully primed and sanded - it should be smooth, shiny and dry. It is recommended to use stains, gouache with the addition of PVA glue, and nitro enamel as a background coating. Apply it with quick movements of the brush, first along the fibers, then across. The product is well dried for 3 - 4 hours and coated with nitrovarnish NTs-218, NTs-221, NTs-222, NTs-228 (with a brush, swab or spray paint) at least twice with intermediate and final drying. The pattern element is glued with a mixture of nitro varnish and solvent (1:3), applying it to the inlaid area with a small brush with soft bristles. At the same time, in the right, working hand, they hold both a scalpel and a brush, holding it between the index and middle fingers (Fig. 54, b).

Technique of a set of elements. They begin to inlay from the center, gradually moving to the right, left, up and down. Simple patterns are made up of various combinations geometric elements: squares, rhombuses, triangles, rectangles (stitches).

A set of simple chains is shown in Fig. 55. It is performed as follows. Nine pairs of parallel guide lines are drawn on the prepared surface at a distance of 10 mm from one another. Using a ruler or compass, divide the surface in half and draw a perpendicular. Between the first two lines there is a chain of square rhombuses. To do this, cut a rhombus from a strip of straw and paste it so that the upper and lower corners coincide with the perpendicular and lie no lower or higher than the guide lines. Then the strip to the right and left of the central diamond is filled with identical square diamonds. In this case, it is necessary to ensure that the corners of the rhombuses touch.

Rice. 55. A set of simple chains: a - from squares, 6 - from rhombuses; c - from triangles; g - from strips (stitches); d - from parallelepipeds.

The zigzag chain is made from narrow rhombuses.

A set of chains of rectangles (stitches) and squares is made up like this. Draw two horizontal straight lines on the surface at a distance of 21 mm from one another. Divide the piece horizontally in half and glue a strip of straw 5 mm wide so that the cut-off rectangle (stitch) of straw 13-15 mm long lies in the middle of the horizontal. Four squares with sides of 2 mm are glued to the four corners of the stitches. Connect the squares with stitches 2 mm wide. Repeat this element first to the left along the guide, then to the right.

Rice. 56. A set of complex chains: a - from large and small squares; b - from squares and stripes (stitches); c - from squares and rhombuses; g - from rhombuses and stitches; d - from rhombuses, squares and stitches.

Complex chains (Fig. 56) are built on the basis of simple ones, usually by building up individual geometric elements up and down from the center.

The border (Fig. 57) is used to decorate the sides of the lids of boxes, chests, and frames. It is made up of combinations of individual geometric elements that form the main pattern. It is assembled from strips no longer than 250 mm.

Rice. 57. Border.

Often the ornament is built from square, rhombic, triangular grids filled with rosettes. The grids (Fig. 58) are drawn using a surface planer, ruler, square and compass. Thin (1-3 mm) strips of straw are glued onto a plane, first horizontally, then vertically. The joints are carefully trimmed, they should be clean and tight. The free space of the mesh is filled with rosettes (Fig. 59). They represent a conventionally depicted open flower of five, six, eight or more petals. Most often, the rosette is made up of rhombuses: the circle is divided into the appropriate number of parts, each of which serves as a cell for the rhombus. Strips of straw can either fit tightly together or form an openwork with additional elements.

In subject compositions, it is sometimes necessary to fill most of the surface with a continuous layer of straw. To do this, strips 5-10 mm wide are glued close to each other, without gaps, changing direction (vertically, horizontally, diagonally), onto the moistened area to be inlaid and carefully rubbed in. The connections at the cut points must be tight and clean.

Straw inlay is especially good when it combines a delicate openwork pattern and a continuous flooring. It is also very important in which direction the strip is placed, as this creates a special play of light and shine.

Having mastered the technique of making inlay set elements and acquired practical skills, you can create interesting, unique compositions with plant, zoomorphic and other motifs.

Application with straws. The basis for it can be wood, plywood, fiberboard, fabric, cardboard, thick paper. The tools and accessories are the same as for inlay.

Rice. 58. Grids.

The technique of applique with straws is as follows. The base, for example plywood, is sanded well, coated with black or brown gouache, and then with wood glue. When the glue dries, transfer the drawing through carbon paper onto the prepared base, as well as onto a thin sheet of paper. Split and smoothed straws of a certain shade are glued (using the laying method) using PVA emulsion to the corresponding elements of the pattern copied on paper. Then these elements are cut out sequentially with scissors and pasted onto the base pattern. The finished application is smoothed along the fibers and pressed with a weight for 10-15 minutes.

The applique uses a wide variety of types of ornaments and decoration techniques, similar to inlay. This technique is used to make decorative panels, frames, postcards, bookmarks, and decor for household items and souvenirs and gifts.

Rice. 59. Sockets.

Combinations of flat, openwork pattern elements with volumetric ones look impressive in appliqués. This technique is often used when creating plant and plot compositions.

There are many options for three-dimensional colors. We recommend starting with the simplest (Fig. 60). A colored or natural golden-colored strip of straw is glued onto a thin sheet of paper. Using a pre-prepared template, cut out a flower petal using nail scissors. The middle of the petal is cut in the form of a triangle approximately to the center. The cut halves are glued together, the resulting petal is glued to the base.

Rice. 60. Volumetric elements, used in straw applications.

Decorative elements are made in the form of tassels, “suns”. For the “sun”, 5-6 well-steamed wet straws 30-50 mm long are tied in the middle. Using a needle, carefully separate each straw into thin strips 1-1.5 mm wide. Bend the top and bottom of the workpiece, connect the ends, straighten them evenly around the circumference, and straighten the ends with scissors. The finished element is ironed or placed under a press.

For a tassel, the straws are also tied in the middle, then bent at the base, tied again, split, straightened and placed under a press.

For the manufacture of various objects for applied purposes, both the tree trunk itself and the growths on it (burl) and on the roots (burl) are used with equal success.

Burl wood, due to the twisted arrangement of fibers and various dark-colored inclusions, has an unusually beautiful texture. In addition, due to the lack of straight layers, it has high strength and hardness; after carpentry it does not crack, warp, swell, does not shrink, and is well polished. The significant hardness of the burl makes it possible to make products from it with thin walls (3-4 mm), light and elegant, and also to use internal hinge devices in them (this is how secretly opening boxes, cigarette holders, etc. are made).

Due to the richness of the patterned wood pattern with the amber-yellow color of the polished surface, burls are considered one of the best materials for creating products of a utilitarian and decorative nature: various boxes, caskets, candy bowls, fruit dishes, powder compacts, cigarette cases, mouthpieces, pipes, chessboards, match holders, etc.

The process of making burl products consists of a number of sequential operations: marking, sawing, steaming, drying, carpentry, polishing and, in some cases, varnishing. The main tool is a set of chisels of different widths and configurations and an electric drill.

The burl is sawn into slices of thickness depending on the size of the intended product. Usually the pattern on a fresh cut of the burl is pale. To reveal the texture, the plates are steamed. Wet sawdust is placed on the bottom of the pan in a layer of about 20 mm, burl plates are placed on them, covered with a layer of wet sawdust and the pan is placed in the oven for 2-3 hours. During the steaming process, the natural dye contained in the mouth guard dissolves in water and, after drying, the texture of the material is colored beautiful colors- from golden amber to dark chocolate. The steamed burl is dried for a week. After this, the various products mentioned above can be cut, turned and glued from the blanks. They are finished by polishing and, if necessary, coated with alcohol shellac varnish.

A novice carver can be advised to make an object of simple shape from burl, for example a vase-plate. The contours of the product are applied to the workpiece with a pencil. Then unnecessary parts are hatched and removed with a chisel. The design of the product is reapplied to the roughly processed surface and processed again: holes are drilled in the intended recesses and then worked with chisels. In this case, you need to take into account the direction of the fibers, their interlacing and zigzag arrangement, and during gouging, make sure that there are no chips.

The surface processed with a cutting tool is somewhat rough, so it needs to be sanded. They are usually sanded with three types of sandpaper: coarse on a fabric basis, fine and velvety on paper.

After sanding, the product can be coated with a thin layer of varnish, then spread with heated beeswax and rubbed with a cloth.

WITH Fragment is also used to decorate a wide variety of products, not only for applique. An applique of small repeating pieces of straw used as a decorative material is called inlay.

The pre-prepared straw must be cut with a sharp scalpel into the required parts. On the surface to be decorated, the location of the parts is marked and they are glued, creating a certain ornament.

Ornament is a pattern built on the rhythmic alternation of visual elements. Its main purpose is to decorate an object, emphasize the shape and beauty of the material used. The main motif of the images is living nature: the sun, stars, trees, flowers, herbs, animals, birds, people, etc. However, the ornament does not convey them in in kind, but stylizes the most characteristic features and shapes.

Squares, triangles, rhombuses, rectangles, lines - the main components of the pattern - in various combinations form a variety of ornaments.

It is better to start mastering the technique of ornament and inlay with simple patterns from a combination of various geometric shapes(squares, rhombuses, triangles, rectangles).

You can make inlay on a sheet of cardboard covered with colored or velvet paper, on a wooden surface (for example, to decorate boxes), on fabric. The composition looks especially beautiful on a varnished wooden surface and on linen fabric.

You can apply parts to the inlaid surface using wood glue. In this case, you need to carefully lubricate one side of the straw with a brush and glue it to the background. If excess glue comes out, it should be wiped off with a napkin. After all the details have been applied, varnish the surface to be decorated.

When inlaying on varnish, use a brush to cover the surface of the product with varnish and very quickly apply the details. This method requires some skill: in your working hand you need to hold both a scalpel and a brush at the same time, while holding the brush between your index and middle fingers.

Any inlay pattern consists of squares, diamonds, triangles and rectangles different sizes. Start inlaying from the center, gradually moving to the sides. The easiest to perform are chains.

Chains

Simple diamond chain

In order to make a simple chain, you need to prepare a certain number of small rhombuses of the same size (there should be enough of them to cover the entire length of the surface to be decorated). Draw two parallel lines on the plane, between which the diamonds will be located. Using a compass or ruler, divide the plane in half and draw a perpendicular. Here is the middle of the surface. Glue one diamond on it, and then glue the rest, moving right and left (Fig. 1, A).

Make sure that the corners of the square diamonds touch and that the top and bottom corners do not protrude beyond the guide lines.

A simple chain can be made from both “lying” rhombuses (with a blunt end at the top) and “standing” rhombuses (with a sharp end at the top) (Fig. 1, b).

An interesting chain is made from rhombuses that touch on one side. This chain resembles an accordion. It looks especially beautiful if you arrange the rhombuses so that the direction of the fibers alternates: vertical in one rhombus, horizontal in the next, then vertical again, etc. (Fig. 1, V).

Rice. 1. Simple chain of diamonds

Simple chain of triangles

This type of chain differs from the previous one only in that triangles are used here instead of rhombuses.

Triangles can be arranged in two ways:

1. Draw two horizontal lines on the plane to be decorated. Prepare triangles of the same size and glue their bases to the bottom line. Make sure that the tops of the triangles do not protrude beyond the top lines and that the corners of the base touch.

2. Place the triangles so that the vertex of the second triangle rests on the middle of the side of the first, and this side is perpendicular to the drawn line. The top and bottom corners should not protrude beyond the guide lines.

Zigzags

Zigzag of narrow stripes

This type of chain is made from narrow short parallelogram strips. On the plane, draw two horizontal lines and many vertical lines at the same distance from each other to make squares. Now lay the strips diagonally across the square. Make sure that the ends of the strips match (Fig. 2).

Rice. 2. Zigzag of narrow stripes

Zigzag of rectangles

Draw three horizontal stripes. Then prepare the rectangles and glue them in a checkerboard pattern so that one wide side of each rectangle touches the middle line, and the other alternately touches the top and bottom lines (Fig. 3).

Rice. 3. Zigzag of rectangles

Rectangles should not extend beyond the lines.

Zigzag of squares and diamonds

Such a zigzag is made up of square rhombuses and rhombuses touching one side. As a result, the zigzag resembles a chain of cubes.

The chain will be more beautiful if you arrange the parts so that the direction of the fibers of the square rhombuses runs along an oblique line, and the direction of the fibers of the adjacent rhombuses alternates: in one rhombus - vertically, in the other - horizontally.

Grids

This type of ornament is the basis for the development of more complex ornamental patterns.

Strips 1–3 mm wide are glued onto a plane, first horizontally and then vertically. Where the strips intersect, the straw strip is carefully trimmed.

Chains and zigzags are most often used for edging the product. The border is used for the same purpose.

Border

The border is used to decorate the sides of lids, boxes, and frames. It is built from combinations of individual geometric elements that form the main pattern, and must in its nature correspond to the overall artistic design. The border can be either complex or simple - from identical repeating elements along the entire perimeter or plane of the product.

Wide border

In order to make this type of border, you need to make two simple chains of square diamonds so that the bottom corner of the top diamond touches the top corner of the bottom one. Then, in each gap between the top and bottom chain, also glue square diamonds, but smaller in size. Now, in the outer corners between the sides of the square diamond chains, glue small triangles with the bases up. Make sure that the sides of the triangles are parallel to the sides of the square rhombuses, and the bases lie in line with the corners of the rhombuses.

Border "Fringe"

Glue a long narrow straw onto the inlaid surface. Next, choose which direction you will direct your fringe and glue the rest of the parts there accordingly. Glue equilateral triangles of the same size to the straw along its entire length. Make sure their corners touch. Then attach square rhombuses to the protruding vertices of the triangles, the width of the side of which should be half the width of the side of the triangle. And finally, glue square rhombuses to the protruding corners of the square rhombuses, but the width of their sides, in turn, should be half the width of the sides of the first rhombus.

Ornamental border

This border is very easy to make. Glue a simple chain of square diamonds onto the surface to be decorated. The upper and lower corners formed straight lines. Glue narrow long straws onto these lines. Then glue very small square diamonds above the top and below the bottom straw. Arrange them so that a line drawn from the top small diamond to the bottom passes through the point of contact of the large diamonds with each other.

Rosettes

Rosettes are often used to decorate a product. This is a conventionally depicted flower with several petals. Rosettes can be made in different ways; they can be simple or quite complex. Usually the squares of the grids are filled with rosettes, but they can also have an independent meaning. Most often, rosettes are made from rhombuses: the circle is divided into the appropriate number of parts, each of them is a cell for a rhombus. The strips of straw can fit tightly or, conversely, form openwork pattern and be supplemented with various elements. Let's start by creating the simplest rosettes.

Rosette of eight petals

Place a compass in the center of the surface to be decorated and draw a circle. Then divide the circle into 8 parts, in each part there will be a rhombus - a petal. Next, mark the center of each part on the circle line. Now place the compass again in the center of the circle and draw a circle with a smaller radius. The lines dividing the large circle into parts will intersect with the line of the small circle. Draw segments connecting the center of each part (which you marked on the line of the large circle) and the points of intersection of the lines of the parts with the line of the small circle. You should get diamonds. Glue on each part, that is, on each resulting diamond, a plate of straw of the appropriate shape.

Figured rosette

Using a compass, make a circle and divide it by diameter into exactly 6 equal parts. Place one diamond of the same size in each part. Place a diamond in the center of the circle as well. Then cut out the middle of each diamond. Glue one small rectangle between the diamonds.

The surface of the product can be inlaid in other ways.

Flooring set

In some cases (especially in large plot compositions) it is necessary to fill a large surface with a continuous layer of straw. In this case, the prepared tape 5–10 mm wide is glued tightly, without gaps, and carefully rubbed in with the blunt end of the knife handle. By changing the direction, the straws can be laid out vertically, horizontally, or diagonally. In this case, it is necessary to carefully monitor the density and cleanliness of the connection in the places of cuts.

Plant and zoomorphic motifs

When working with straws, such patterns have a geometric shape. Flowers, leaves and herbs can be made openwork, by laying or in combination.

The ornament must correspond to a certain rhythm - that is, the pattern must alternate naturally, its elements must be repeated or subordinated. The pattern should be distributed harmoniously on the surface to be decorated. Rhythmic construction is achieved using various techniques:

♦ rapport pattern construction – various types grids of squares, rhombuses, triangles are filled with pattern elements;

♦ symmetrical construction - a harmonious arrangement of elements of the same type relative to a horizontal or vertical axis or two intersecting straight lines, when the pattern is repeated relative to the axis of symmetry in an image inverted by 180°;

♦ ornamental ribbons, which consist of identical elements. They can be repeated, alternated, or arranged according to the principle of increasing and decreasing rhythm;

♦ centric construction – the elements of the pattern are located on the same straight line, but in different directions from the central point;

♦ asymmetrical, random arrangement of the pattern.

Inlay – a unique way of decorating a surface, in which decorative elements are partially recessed into the surface to be decorated and create a single plane with it.

This is a glue-free way to make a composition. If we take a strict understanding of the term “inlay”, then when applied to working with straw this is not entirely accurate, because inlay involves preparing a nest for a buried element, but due to the small thickness of the straw part and the unique way of fixing it on the surface, it is customary to call applying a straw pattern to wood as inlay, and to paper and textiles as appliqué.

By technology There are two methods of inlay:

Inlay on the ground

Inlay on varnish.

Inlay on the ground. To prepare the primer in a glass bottle in a water bath, prepare the following composition: wood glue - 400 g, water - 500 g, aniline dye - 8 g, glycerin - 40 g, soap shavings - 8 g.

Glue is poured cold water for 6-12 hours. Then cook until softened. Add dye, glycerin, shavings, stirring for 20-30 minutes, bring to a boil, but do not boil.

The solution should be viscous, but flow freely from the brush, forming a drop on the surface of the wood. The finished solution is filtered through a fine sieve or gauze. Apply with a brush or spray no more than 2 times. Each layer is dried for 4-5 hours, the first is sanded along the grain with fine sandpaper. The primed surface must be well sanded, smooth and shiny, and dry.

The principle of performing inlay "on the ground". The place where it is necessary to glue the inlay element cut from straw is lightly moistened with water using a brush or finger. Thanks to the glycerin and soap it contains, the wetted soil almost instantly swells and becomes sticky. While it retains its viscosity, a part cut from straw is pressed against it and smoothed. It is rubbed on top with the end of the handle of the knife-jamb. After some time, the soil hardens again and firmly grasps the straw planted on it.

When inlaid on varnish The varnish is first applied with a brush, swab or spray at least twice along and across the fibers (NTs 218, 221, 222, 228). Each layer is well dried. Since the varnish used for priming is transparent, wood products are pre-painted with various stains, aniline (textile) dyes, gouache paints, and ink. To strengthen the adhesion of wood to gouache, add a little PVA glue to it. Straw parts are glued with a mixture of nitro varnish and solvent in a ratio of 1:3. A drop of the composition is applied with a brush at the intended location of the element, thereby softening the varnish layer and making it viscous, capable of holding the straw plate. The brush and scalpel are held in one hand, changing their position as needed. At this moment, the tip of a straw strip is placed on it and a diamond, square, triangle, etc. is cut off from it (depending on the need). The pattern element placed on the varnish is smoothed with the end of the handle of the knife-jamb, trying to press it as tightly as possible to the surface of the thing being decorated. subject. The next and all other elements of the pattern are also glued on. At the same time, make sure that the corners of the geometric straw figures coincide with the applied auxiliary lines.

Basic types of pattern construction in inlay

A) rapport construction - grids of squares or rhombuses are filled with pattern elements

B) symmetrical construction - the arrangement of elements of the same type relative to a horizontal or vertical axis, when the pattern is repeated with a rotation of 180 degrees.

C) ornamental ribbons - consist of identical elements, can be repeated or alternated, can be arranged according to the principle of decreasing or increasing rhythm

Inlay – a unique way of decorating a surface, in which decorative elements are partially recessed into the surface to be decorated and create a single plane with it.

This is a glue-free way to make a composition. If we take a strict understanding of the term “inlay”, then when applied to working with straw this is not entirely accurate, because inlay involves preparing a nest for a buried element, but due to the small thickness of the straw part and the unique way of fixing it on the surface, it is customary to call applying a straw pattern to wood as inlay, and to paper and textiles as appliqué.

By technology There are two methods of inlay:

Inlay on the ground

Inlay on varnish.

Inlay on the ground. To prepare the primer in a glass bottle in a water bath, prepare the following composition: wood glue - 400 g, water - 500 g, aniline dye - 8 g, glycerin - 40 g, soap shavings - 8 g.

The glue is poured with cold water for 6-12 hours. Then cook until softened. Add dye, glycerin, shavings, stirring for 20-30 minutes, bring to a boil, but do not boil.

The solution should be viscous, but flow freely from the brush, forming a drop on the surface of the wood. The finished solution is filtered through a fine sieve or gauze. Apply with a brush or spray no more than 2 times. Each layer is dried for 4-5 hours, the first is sanded along the grain with fine sandpaper. The primed surface must be well sanded, smooth and shiny, and dry.

The principle of performing inlay "on the ground". The place where it is necessary to glue the inlay element cut from straw is lightly moistened with water using a brush or finger. Thanks to the glycerin and soap it contains, the wetted soil almost instantly swells and becomes sticky. While it retains its viscosity, a part cut from straw is pressed against it and smoothed. It is rubbed on top with the end of the handle of the knife-jamb. After some time, the soil hardens again and firmly grasps the straw planted on it.

When inlaid on varnish The varnish is first applied with a brush, swab or spray at least twice along and across the fibers (NTs 218, 221, 222, 228). Each layer is well dried. Since the varnish used for priming is transparent, wood products are pre-painted with various stains, aniline (textile) dyes, gouache paints, and ink. To strengthen the adhesion of wood to gouache, add a little PVA glue to it. Straw parts are glued with a mixture of nitro varnish and solvent in a ratio of 1:3. A drop of the composition is applied with a brush at the intended location of the element, thereby softening the varnish layer and making it viscous, capable of holding the straw plate. The brush and scalpel are held in one hand, changing their position as needed. At this moment, the tip of a straw strip is placed on it and a diamond, square, triangle, etc. is cut off from it (depending on the need). The pattern element placed on the varnish is smoothed with the end of the handle of the knife-jamb, trying to press it as tightly as possible to the surface of the thing being decorated. subject. The next and all other elements of the pattern are also glued on. At the same time, make sure that the corners of the geometric straw figures coincide with the applied auxiliary lines.

Basic types of pattern construction in inlay

A) rapport construction - grids of squares or rhombuses are filled with pattern elements

B) symmetrical construction - the arrangement of elements of the same type relative to a horizontal or vertical axis, when the pattern is repeated with a rotation of 180 degrees.

C) ornamental ribbons - consist of identical elements, can be repeated or alternated, can be arranged according to the principle of decreasing or increasing rhythm

D) centric construction - the elements of the pattern are placed on the same straight line, but in different directions from the center point

D) free distribution of the pattern over the entire surface. They are used in asymmetrical compositions, often of a plot nature.

Inlay technology

Basic tool, used for inlaying with straws is a jamb knife. The master should have several knives at his disposal with different blade angles. It is necessary that the handle gradually tapers towards the blade, and has a beveled end on top - it is used to smooth out the glued straws.

When applying all sorts of parallel lines to the inlaid product, surface planers are used, both factory-made and homemade. The thicknesser consists of a block with through holes into which one or two rods with strong needles driven into the ends are inserted.

To split the straw into strips of equal width, special cutters are used. Each cutter is a round wooden stick, at the end of which there are two thin needles with their points facing outward. The distance between them should be equal to the width of the straw strips. You need to have several of these cutters, which have different distances between the tips of the needles. To split the straw into two or three identical strips at once, use a cutter with three or four needles driven in at an equal distance from each other.

To cut out identical pattern elements from straw in the shape of a circle, oval, flower, etc., special punches made of steel tubes are used. The straw elements are pushed out of the punches and out of the thick wire.

Glue or varnish is applied to the inlaid surface using a soft brush knitted from squirrel hair. To make the brush comfortable to hold in your hand, its length should be no more than 150 mm.

Basic operating techniques

Marking. The drawing cannot be transferred to the background. Mark the main lines of the drawing using a compass and ruler, using a thin needle. Circles and arcs are marked using a compass or meter.

Stem splitting. The straw is split, smoothed into a ribbon, and then divided lengthwise into strips of the required width. Using cutters, calibrated strips, that is, having a certain width, are cut from the prepared material.

Preparation of elements. Identical elements of future patterns (diamonds, triangles, squares, trapezoids and parallelograms) are cut off from the calibrated strips with a jamb knife on a wooden cutting board or directly on the surface to be inlaid. The straw strip is pressed to the wood surface with the left hand, and the right hand holds the joint knife and the brush at the same time

Inlaid, starting with the main element (socket), gradually moving to the right, up, left.

Main motives of inlay

Chains– narrow tapes consisting of homogeneous or repeating geometric elements. There are chains simple– consisting of identical elements, complex- consisting of different elements, but repeated in a certain rhythm. Complex chains are usually a little wider.

Border- a pattern for decorating the edges and side walls of products. Constructed from combinations of individual geometric elements that form the main pattern (sometimes simple and complex)

Roseta– a conventionally depicted open flower of 5-8 petals. Rosettes fill the squares of the grids, but they can be the middle of the patterns. Mark the rosettes using a compass, limiting the circumference of the edges of the petals and dividing it into equal parts according to the number of petals.

Grids- planes divided into cells of various shapes by narrow straw strips or chains, which form the rapport character of the ornament and are the basis for the development of more complex ornamental patterns. To make meshes, thin strips (1-3 mm) are glued first horizontally, then vertically, cutting at the intersection points.

Floorings– areas completely covered with straw strips located in different directions

Plant and zoomorphic motifs- stylized images of plants and their parts, as well as animals and humans. When inlaid, they have a stylized geometric shape.

The final finishing of the inlay involves the removal of traces of markings, glue stains, as well as subsequent varnishing of the work. At the same time, the surface of the straw acquires a protective layer, becomes more glossy and bright, and a layer of varnish masks traces of markings with a needle.