Of the various physical and mechanical properties of raw fur skins, the following are of greatest importance in determining their use value:

Hair properties: height, thickness, length individual categories hair, thickness of individual categories of hair, softness of hair, elasticity, curlability, tensile strength of hair, shine.

Properties of the skin: thickness, tensile strength.

Properties of the skin as a whole: weight of the fur skin, area, heat-protective properties and wearability.

Properties of hair

Hair height is the shortest distance from the skin to the ends of the covering hair, taking into account the angle of the hair in the skin. The hair of nutria is low and adjacent.

An indicator of hair density for fur is usually considered to be the number of hairs (pieces) per 1 cm2. In animals leading a semi-aquatic lifestyle, as a rule, the hair on the scalp is thicker than on the ridge. By direct calculation of the number of all types of hair per unit area, it was established that there are about 5.9 thousand hairs on the dorsal area, 14.0 thousand hairs on the calves, and 12.5 thousand hairs on the sides.

The hair of nutria consists of three types of hair: guide, guard and down. Hair of these types differs in shape, length and fineness, and morphohistological structure.

Guide hairs are the longest of the hairs covering the nutria's body. Their shape is lanceolate; length at the ridge - 41-70 mm, fineness - 189-258 microns. In a cross section, three layers are distinguished: cuticular, cortical and medullary. The guard hairs also have a lanceolate shape, but flattened. They have a well-defined grain, a thinned neck and base of the hair. Arranged in several tiers, the guard hairs well protect the underfur from external factors. The length of the spine is 20 - 37 mm, fineness - 39 - 211 microns. On a cross section of hair, three layers are also distinguished. Downy hair is the shortest and thinnest. They make up 92-97% of the total amount of hair on the skin. The grain of downy hair is not pronounced, the shaft is crimped. The length on the spinal part of the skin is 15-26 mm, fineness is 12-15 microns. Hairs in the skin tissue of nutria are arranged in groups of 20-150 pieces. Since the process of hair growth, especially in young animals, is continuous, groups can include growing hair (with the presence of a core layer in the root part) and completed growth (without a core layer in the root part). The length of hair in different topographic areas of nutria skins is not the same. Most long hair located on the ridge, the lower one - on the womb. Based on the length of the covering and down hairs, the area of the skin can be divided into four zones.

Table 2 - Hair length on nutria skins

The length of nutria hair is directly dependent on the age of the animals.

Softness of the scalp - a feeling of the degree of elasticity of the scalp when it is compressed. The hair of nutria consists of very thick (especially on the head), silky down, covered with a thick, long, coarse spine.

Elasticity is the property of hair to return after creasing to its original or close to it state. Guard hairs are much more elastic than down hairs. During molting, elasticity is at its lowest. The less elasticity of the hairline, the easier it becomes felted (feltability is the property of hair, when entangled with each other, to form dense felt-like masses, the defect is “matted hairline”).

Hair tensile strength is the ability to resist external forces that destroy its integrity or change its shape. Tensile strength is determined by the force that must be applied to break their rod. Hair strength largely determines wearability fur products. The tensile strength of guard and guide hairs usually greatly exceeds that of down hair.

The coloring of semi-finished fur products depends on the content of pigments (dyes) in the hair shafts. Currently, nutria are bred with standard (wild) and colored forms of fur color. On the farms of our country, amateur nutria growers breed more than 10 different color forms nutria. The development of colored nutria farming was facilitated by the population's demand for products made from such skins. On nutria skins, spots of a different color (pejins) are a defect.

Gloss is the ability of the surface of the hair to reflect the rays of light falling on it. The degree of shine depends on the size, shape and location of the cuticle scales, as well as on the structure of the hairline: guard and guide hairs increase shine, downy hairs make the hairline matte. An indicator of the quality of nutria skin is the pronounced shine of the coat.

Properties of the skin

In adult nutria, the epidermis is distinguished in the skin tissue with a different number of layers depending on the presence or absence of the intensity of the anlage, growth and formation of new hair. The number of these layers can vary between 2-5. In the dermis there is a well-defined thermostatic layer, penetrated by hair roots located at an angle of 35-400, including horizontally intertwined collagen, elastin and reticulin fibers, cellular elements, sebaceous and sweat glands. The thickness of this layer is 70-90% of the entire thickness of the leather fabric. The reticular layer is somewhat less pronounced, mainly consisting of tightly intertwined collagen bundles with a looped structure. This layer reaches its greatest development in the period preceding the most intense periods hair shedding (spring/autumn). At this time, the mesh layer can account for 20-25% of the total thickness of the skin tissue, during the formation and growth of new hair - 12-15%. Under the reticular layer is subcutaneous fatty tissue. In young nutria, the skin is different in that it has no reticular layer at all, thin weakly intertwined collagen fibers, small sebaceous and sweat glands, hair roots with the tops of the bulbs lying on the surface of the fatty tissue.

The thickness of the skin depends on the topographic area, the time of extraction, gender and age, individual characteristics animal. The skin tissue of nutria skins is medium in thickness and elastic.

The skin of nutria varies in thickness in different topographic areas: it is thickest on the ridge (from the middle of the ridge to the root of the tail), less thick on the sides, head, and tail, and thin on the womb.

The depth of growing hair is 800-850 microns, finished growth is 350-400 microns, with the thickness of the skin tissue being 1100-1200 microns.

The tensile strength of the skin determines the wearing time of fur products made from skins. The tensile strength of leather fabric depends on the topographic area on the skin. Thus, the strength of the longitudinal straps on the ridge is 20.7, the transverse ones are 4.9 kg, and on the womb, respectively, 5.8 and 2.0 kg.

Properties of skins in general

The size of the skin is determined by its area. The area of the skin depends on the sex and age of the animal, individual characteristics and habitat. The area of the skins also depends on the method of preservation. During fresh-dry canning, the area of the skins is reduced by approximately 10% of the area in the paired state.

The area of nutria skins is determined by multiplying the length measurements from the middle of the interocular to the line connecting the lateral points of the rump by twice the width in the middle of the length of the skin.

In raw materials, the length of nutria skins of various sizes ranges from 35-75 cm, width - 25-53 cm. The area ranges from 600 to 2000 cm2.

The weight of the skins depends on the thickness of the skin tissue, the thickness and length of the hair, the area of the skins, the season of extraction (or slaughter) of the animals, methods of preservation and other factors.

Thermal protective properties primarily depend on the air that is between the hairs of the skin and inside the hair in their core channels, as well as on the density of the skin tissue. The longer and thicker the hair and the denser the skin tissue, the higher the heat-protective properties of the skin.

In nutrias, the heat-protective properties of fur also depend on the age of the animals. In nutria with secondary hair, this indicator is 0.418 W/mChk, at 7 months of age - 0.193, at 10 months of age - 0.282; for skins of the 1st grade - 0.186, for the second - 0.140.

The durability of the skin is determined by the degree of resistance of its hair and leather tissue to various destructive influences that it experiences during operation. The wearability of a fur product determines the duration of its use.

Nutria have average fur wear. If the wearability of otter fur is taken as 100%, then the wearability of natural nutria fur is 50%, and plucked fur is 25%. According to commodity experts, the durability of nutria fur is equal to 5 seasons (one season includes 4 months).

From the above it is clear that all the properties of nutria skins are influenced by many factors: breeding work, feeding, maintenance, age of the animals, slaughter season, etc. Therefore, it is important for nutria breeders to constantly improve the selection of animals, observe optimal timing slaughter, improve primary processing of raw materials. A standard assessment of raw materials is required, taking into account objective quality indicators.

1.13, section 4

6. By Decree of the State Standard of January 14, 1992 N 7, the validity period was lifted

7. REISSUE (April 1997) with Change No. 1, approved in January 1992 (IUS 5-92)

This standard applies to tanned, undyed and dyed, unshorn and sheared, as well as with the awn removed, nutria skins intended for the manufacture of fur products.

The requirements of this standard in terms of sections 1, 3, 4 are mandatory.

1. TECHNICAL REQUIREMENTS

1. TECHNICAL REQUIREMENTS

1.1. Nutria skins must be tanned in accordance with the requirements of this standard using technology approved in the prescribed manner.

1.2. The skins must be dressed in a layer with an even cut in the middle of the womb, preserving the fur of the head and symmetrically straightened.

1.3. The leather fabric should be soft, clean and give stretch in all directions.

1.4. The hair must be clean, combed, and evenly trimmed on shorn skins.

The hair of skins with the hair removed should consist of downy hair.

The hair of dyed skins must be free of stains and unpainted areas.

On dyed skins, transitions in color intensity from the ridge to the belly are allowed; from awn to down.

1.5. Tears, holes, and bald spots must be repaired without disturbing the symmetry of the skins.

1.6. (Deleted, Amendment No. 1).

1.7. The chemical and physical-mechanical properties of the skins must comply with the standards specified in Table 1.

Table 1

Indicator name | |

Mass fraction of moisture in leather fabric at the time of sampling, %, no more | |

Mass fraction of unbound fatty substances in leather tissue in terms of absolutely dry matter, %, no more | |

Mass fraction of chromium oxide in leather fabric in terms of absolutely dry matter, %, no more | |

undyed skins | |

dyed skins | |

Leather fabric welding temperature, °C, not lower | |

pH of water extract of leather fabric, not lower | |

Load when breaking a whole skin, N (kgf), not less | |

Color fastness of dyed skins to dry friction on a scale of gray standards, points, not less | |

black | |

in other colors |

1.8. Depending on the color of the hair, nutria skins are divided in accordance with Table 2.

Table 2

Coloring | Description of hair color |

Skins, undyed, unshorn and shorn |

|

Black | Covering hairs on the ridge are almost black to black, on the mantle from black to dark brown; downy hair - from dark gray to dark brown |

Brown | The covering hairs on the ridge are greyish-brown to dark brown; the hair on the mantle is lighter in color than on the ridge. The guard hairs on the ridge and sides have a zonal coloration; downy brown hair of varying intensity |

Pastel | Covering hairs of pure brown color of varying intensity; downy hair - light brown to brown |

Mother of pearl | Covering hairs from light brown to beige color with lightened tops, the hair color on the womb is lighter than on the ridge; downy hair - from beige to almost white. A yellowish tint to the coverts and downy hair is allowed |

Golden | The covering hairs on the ridge are from orange to light yellow with a golden tint; on the mantle the hair color is lighter than on the ridge; downy hair is yellow in color of varying intensity. Darker tops of downy hair are allowed |

Covering and downy hairs are white. |

|

Undyed skins with hair removed |

|

Black | From dark gray to dark brown with a black tint |

Brown | Dark brown on the ridge; brown or light brown on the tail |

Dyed skins, unshorn, shorn, and also with the awn removed |

|

Black | Black color throughout |

Colored | Various colors except black |

Note. Nutria skins, uncut, undyed, of other colors are accepted by agreement with interested organizations.

1.9. Depending on the condition of the hair, nutria skins are divided into varieties in accordance with the requirements specified in Table 3.

Table 3

Characteristics of the hair of the skins |

|||

uncut | shorn | with removed spine |

|

First | Full-haired, with a shiny awn, thick down and a well-furred belly | Dense, with shiny frequent awns and thick down. | Silky with thick fluff |

Second | Less full hair, with underdeveloped awns and down, or less dense hair coat | Less dense, with thinning awns and down | Down is less dense and less silky |

1.10. Depending on the presence of defects, nutria skins are divided into groups in accordance with Table 4.

Table 4

Name of the vice | Group |

|||

first | second | third | fourth |

|

1. Seams with a total length equal to the length of the skin | Up to 0.25 incl. | St. 0.25 to 1.00 incl. | St. 1.00 to 2.00 incl. | St. 2.00 to 2.50 incl. |

2. Holes, bald spots, worn out hair, snacks, spots of a different color (pejins) by total area, % | Up to 0.5 incl. | St. 0.5 to 1.5 incl. | St. 1.5 to 3.0 incl. | St. 3.0 to 5.0 incl. |

3. Exposure of hair follicles or through hair with total area, % | Up to 3.0 incl. | St. 3.0 to 10.0 incl. | St. 10.0 to 20.0 incl. | St. 20.0 to 40.0 incl. |

4. Brokenness (section) of the spine, total area, % | Up to 1.0 incl. | St. 1.0 to 5.0 incl. | St. 5.0 to 10.0 incl. | St. 10.0 to 15.0 incl. |

5. Presence of spine on skins with removed spine total area, % | Not allowed | Up to 5.0 incl. | St. 5.0 to 10.0 incl. | St. 10.0 to 15.0 incl. |

6. Absence of parts of the skin | Heads | Heads with necks | ||

Notes:

1. The size of the defects indicated in subparagraphs 2-5 of the table is determined by the area of the smallest rectangle into which these defects fit.

2. Defects located at a distance of no more than 1 cm from the edge of the skin and spots of a different color (pink marks) on the head are not taken into account.

3. Skins cut along the ridge are classified as defect group “four”.

1.11. More than one defect of this group is not allowed on skins.

In case of a combination of various defects, the following is allowed:

on skins of group “second” - no more than two defects of group “first”;

on skins of group “third” - no more than two defects of group “second”;

on skins of group “four” - no more than two defects of group “third”, or a combination of one defect of group “third” and two defects of group “second”, or four defects of group “second”.

If there is a combination of one defect of the highest group and one defect of the lowest group, the skin is transferred to the next lower group.

1.12. The quality of the skins is assessed in accordance with the application.

1.13. Labeling and packaging of skins - according to GOST 19878 with the following addition:

The following quality characteristics must be marked on the leather fabric of each skin:

by color | by variety | by groups |

unpainted | first - 1 | first - 1 |

black - 1 | second - 2 | second - 2 |

brown - 2 | third - 3 |

|

pastel - 3 | fourth - 4 |

|

mother-of-pearl - 4 | ||

golden - 5 | ||

white - 6 | ||

painted | area, dm | |

black - 1 | ||

colored - 2. |

(Changed edition, Amendment No. 1).

2. ACCEPTANCE RULES

GOST 9212

The measurement result is rounded to 1.0 dm.

3.10. Measuring the skin, seams and cutting height are carried out with a metal ruler or tape measure with a division value of 1 mm.

4. TRANSPORTATION AND STORAGE

Transportation and storage of skins - in accordance with GOST 19878.

(Changed edition, Amendment No. 1).

APP (recommended). TABLE assessing the quality of processed nutria skins in percentage

Group of vices |

|||||

first | second | first | second | third | fourth |

Note. Skins that do not meet the requirements of Table 3 of this standard, skins with defects exceeding the norms established for group "four", as well as skins with very sparse hair, half-haired skins, skins of cubs with plump hair must have a quality rating of no more than 25 % of the assessment of the quality of skins of the first grade and group “first” of the corresponding color.

(Changed edition, Amendment No. 1).

The text of the document is verified according to:

official publication

M.: IPK Standards Publishing House, 1997

The timing of nutria fur maturation depends to some extent on the feeding of the animals. It has been scientifically proven that reducing the level of animal feeding by 25% slows down the maturation of their hair coat and also negatively affects its quality, while increasing the feed ration by 25%, on the contrary, accelerates the maturation of fur by approximately 2 weeks.

Depending on the climatic zone of breeding, nutria exhibit a certain change in the density of downy hair.

Thus, in the northern zones, the underfur of nutria is thicker, and accordingly, their fur is valued more highly. In this regard, it is recommended to slaughter animals in the northern regions of the European part of Russia from November to mid-March. In the central zone, animals are slaughtered from the second half of November to March, and in the southern zone - from early December to March.

The value of nutria skin

The value of nutria skin depends on its size, coat color, strength, thickness, height, uniformity of hair, as well as on the degree of defectiveness of the hair and skin and, of course, the quality of the initial processing of the skin. All these factors determining the quality of nutria fur, in turn, depend on the time of slaughter and the age of the animals, the conditions of their keeping and feeding.

It is best to slaughter nutria selectively, by individually assessing the ripeness of the coat. To do this, the nutria to be slaughtered is lifted by the tail and, after carefully examining it, the condition of its fur is assessed.

The main indicator of the ripeness of the fur is the regrown covering hairs on the lower part of the abdomen and on the inner surface of the thighs, where the coat of nutria is the last to form. In addition, the animals to be slaughtered should have a well-equated inguinal part of the pubescence, and the underfur of the ridge and abdomen should be silky, without signs of matting. Such skins, obtained from animals aged 9 months and older, are of the highest quality and belong to grade I.

Skins belonging to grade II and obtained from animals aged 6–7 months, as a rule, have a less bright color than skins of grade I, and a brownish coating on the rump. In addition, in such skins the zonation of the covering hairs is less pronounced; on the front part of the body the underfur is shiny, and on the rump it is dull. The groin part is slightly less pubescent, and the downy hairs are no more than 8 mm high (on grade I skins the downy hairs are 10 mm high).

When planning the timing of nutria slaughter, they pay attention not only to the grade of the skin, that is, to the height and density of the downy hair, but also to its size. According to the standard, nutria skins are not divided by size, but are taken by area, determined in square decimeters. To do this, the measurement from the middle between the eyes to the line connecting the side points of the rump is multiplied by twice the width of the skin in the middle. A value of 0.5 dm 2 or more is considered 1 dm 2, less than 0.5 dm 2 is not taken into account at all.

Skins with an area of 20 dm2 can be obtained from 6-month-old nutrias that weigh at least 4 kg and have a body length of at least 50 cm.

Slaughter of nutria

A few days before the slaughter of animals, it is necessary to prepare inventory, premises and equipment for processing the skins. As a rule, nutria are slaughtered early in the morning. 12–15 hours before the expected slaughter of animals, they stop feeding and drinking. They are not allowed to swim for the same amount of time.

Slaughtering nutria requires certain skills, and if the owner doubts that he can carry out this very serious undertaking without outside help, he needs to contact a specialist who has experience in slaughtering nutria or other fur-bearing animals.

To slaughter nutria, as well as some other fur-bearing animals, they use a flat short stick (aspen, birch, linden or oak) 50–60 cm long, 5–6 cm thick and wide. When slaughtering an animal, a stick previously wrapped in fabric or covered with rubber held so that its center of gravity is slightly shifted forward.

At the moment of slaughter, the nutria must be lifted with the left hand by the tail and hind paw and the animal must be killed with a strong and sharp blow of a stick on the back of the head (behind the ears) or forehead. Although the blow must be made in such a way that the animal dies instantly, at the same time it should not be too strong so that the skull and bridge of the nose of the nutria remain intact. In addition, there should be no bruises on the inside of the animal’s head from the blow.

Immediately after slaughter, the nutria carcass is bled, for which purpose the sublingual, jugular veins and other vessels are cut through the mouth. This is done with a sharp-pointed knife, which is inserted between the lower incisors and lower lip (without damaging the skin) to the cervical vertebrae, and then cut with semicircular movements of the knife in both directions blood vessels. Some nutria doctors make similar incisions through the nasal openings.

After carrying out the above procedure, the carcass is hung by the hind leg and a basin is placed under it, into which the blood will drain.

After complete bleeding, the nutria carcass is removed from the hook and the urine is removed from it, for which, holding the carcass with one hand by the head, with the other hand, lightly pressing, pass it along the belly several times. Then, over the next few hours, the skin is removed and the carcass is cut up.

Removing the skin

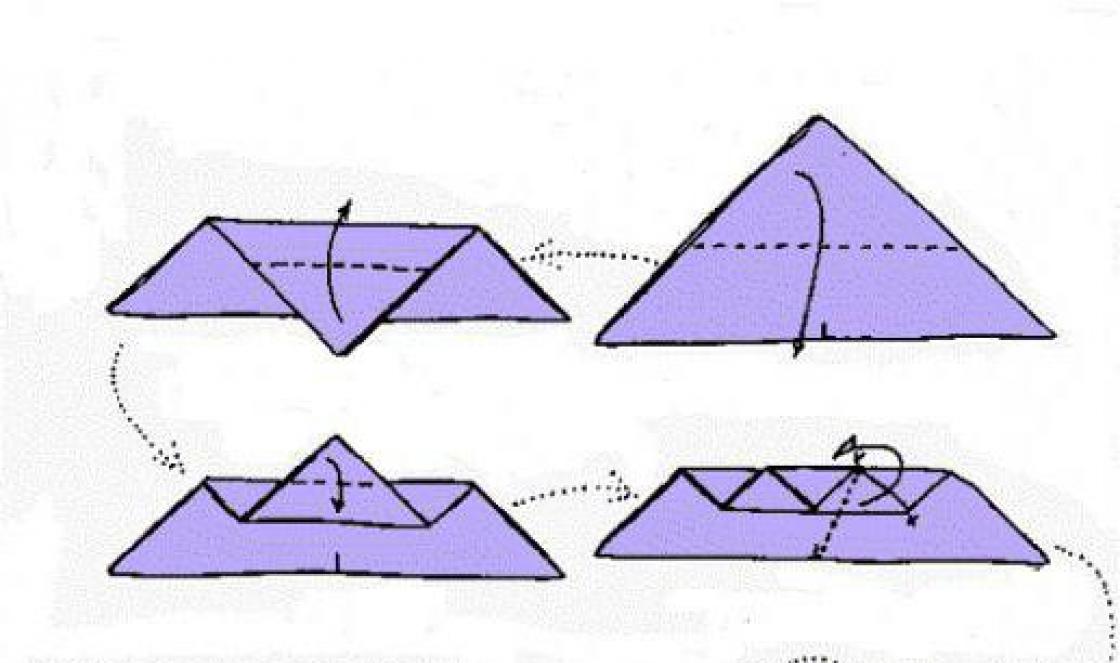

Immediately after bleeding, the skin is removed from the carcass. The skin is removed using a tube, starting from the lower part of the body (rump) and ending with removal from the head. Before harvesting begins, cuts are made on the skin, for which the carcass is hung at chest level on a hook by the leg or tail (on a rope loop) and with a well-sharpened knife, circular cuts are made in the skin on the paws, at the border of their pubescence, and the tail is cut off at the border of the pubescence. , then a connecting skin incision is made along the outer thighs from the hock joint from one hind leg to the other (Fig. 29).

Rice. 29. Skin cut lines when removing the skinThe incision is made in such a way that the strip of skin from the rump passes to the ventral side. This cutting method prevents the appearance of a notch on the skin along the edges of the belly after drying. The anus is cut around, and the genitals of males are removed.

Then the carcass is placed on its back on a table or other horizontal surface and the skin on the thighs, groin and rump is separated with a knife. Afterwards, the skin is pulled down, the rectum and connective muscles are trimmed, and the skin is separated from the muscles of the back, abdomen and chest to the front paws. The skin removed from the front paws is very easily pulled away from the head.

To avoid contamination of the skin with blood, sawdust is poured onto its neck part or paper is placed in the form of a cuff.

When removing the skin from the head, take it not by the rump, but as close to the neck as possible. At the same time, pulling it together with the left hand, the muscles, ear cartilage, as well as the skin around the eyes and lips are carefully trimmed with the right hand. During the skinning process, the connective tissue that interferes with the separation of the skin from the carcass is trimmed with a knife and thoroughly cleaned of the subcutaneous layer of muscle and fat, trying to do this with extreme caution to prevent cuts.

Under no circumstances should you pull the skin too hard, as the skin on it will stretch too much, causing the fur to thin out.

Degreasing the skin

Immediately after removal, the skins are degreased, for which, using wooden blocks, on which the skin is pulled with the fur inward, the remaining fat and meat are cleaned from the skin. The blank is made from dry wood, round in shape, 14–15 cm in diameter, 75–100 cm long.

The narrow end of the blank is installed in a stop nailed to the bench. To do this, resting your chest on the wide end, the blank is pressed forcefully against the stop. To make their work easier, most nutrievods strengthen the blank for degreasing the skins on the machine (Fig. 30).

Rice. 30. A blank mounted on the machine for degreasing skins (dimensions are given in mm)

Rice. 30. A blank mounted on the machine for degreasing skins (dimensions are given in mm)The most convenient for degreasing skins are knives with a rounded handle, a straight blade and a slightly curved tip. The knife must be rigid and very durable.

To degrease nutria skins, knives with a blade length of 11–13 cm, a thickness of 2 mm and a width of 3 cm are used. The length of the knife handle must be at least 10 cm, and its diameter must be at least 2.5 cm.

The technique for degreasing skins is quite simple, but it requires some experience. With your left hand you grab the edges of the skin and pull them towards you, and with your right hand you trim and remove the muscle film and fat and meat remaining on the skin towards the head. In this case, it is advisable to hold the knife blade at an angle of 40–45° relative to the surface of the flesh. As for the remnants of muscle tissue in the area of the mouth, it is removed with surgical scissors.

The degreased skin is thoroughly wiped with sawdust or a clean cotton rag.

Drying skins

Before you start processing the skins, they need to be dried. Drying is carried out in well-ventilated rooms at a temperature of 25–30 °C, placing the skins with the skin or hair facing out. In addition, you can dry the skins in specially designed rooms using heating units. The air temperature in such rooms should be 20 °C. Drying time at a temperature of 25–30 °C is 4–6 hours, and at 20 °C – 12 hours. Air humidity for both drying methods should be 40–60%.

Droplets of fat that appear on the surface of the flesh during rapid drying are removed with a dry cotton rag.

You cannot dry skins at temperatures below 20 °C and with poor ventilation, since in this case the skins become heated and become unsuitable for dressing. In turn, drying at temperatures above 30 °C causes the flesh to become brittle, and such skins also cannot be tanned. The dried skin should be elastic and have a moisture content of about 14–16%.

Drying of nutria skins is carried out on racks, and the distance between the rows must be at least 20 cm. The skins are also dried in horizontal position or with a slight slope on special rules, the distance between which should be 10–15 cm.

During drying, you need to ensure that the flesh dries evenly, so the rules with skins are installed in such a way that the front paws do not come into contact with the flesh under the arms (sometimes paper is placed under the paws). If necessary, the rules are swapped or turned over.

It is not recommended to dry skins near a heat source. For example, if the temperature in the drying room is maintained above 25 °C, then the skins should be located at least 1.5 m from the heat source.

Special sliding rules are used to give the skins a standard shape, as well as for uniform and more quick drying (Fig. 31).

Rice. 31. Rule for straightening skins (dimensions are given in mm)

Rice. 31. Rule for straightening skins (dimensions are given in mm)For such drying, defatted nutria skins are put on straighteners with the flesh outward and placed in the dryer, paying special attention to the shape of the skins.

A universal straightener for drying nutria skins consists of two smoothly planed slats, rounded along the outer edge, movably fastened at the top with a metal plate. At the bottom of the planks, slots are made for a transverse spacer (with its help, the rule can be moved apart to the required width). The spacer is attached to one of the planks with a metal rivet, and to the other with a nail or screw.

Many nutria growers use rules made of wire wrapped in cellophane or insulating tape with a cross-section of 6–8 mm. This rule is made from a 2 m long wire rod, which is bent in half and its ends are secured with twine or a plywood spacer. The width of the rule is set according to the size of the skin.

The nutria skin is put on the rule in such a way that it is not too stretched, while the upper cone-shaped part of the rule should rest against the nose of the skin from the inside.

The holes for the ears, eyes, and front paws are placed symmetrically on the corresponding sides. The tip of the nose and the base of the tail should be in the middle line of the rule. After placing the skin on the straightener, you need to straighten out all the folds and irregularities on it with your hands.

To prevent shrinkage during drying, the skin stretched over the straightener is secured with nails or metal rods, which are driven into the nose and through the holes of the front paws, after inserting pieces of paper there.

The lower part of the skin is attached from the side of the ridge, trying not to stretch the skin in length. Some experts secure the rump by wrapping twine around its lower edge.

Skinning

Tanning nutria skins, as well as any other skins, at home is a very labor-intensive task, since this operation includes many rather complex technological processes:

– preparatory process, including degreasing, washing and soaking;

– dressing, that is, pickling, tanning, fatliquoring;

– finishing (drying, skin and fur cosmetics).

Degreasing. To degrease, the skins are placed in a bath of water, the temperature of which should not be lower than 35 °C, for 1 hour. To degrease the skin, use any detergent, which is added to water at the rate of 3 g per 1 liter.

Flushing. After degreasing the skin, the nutria are thoroughly washed clean water. Washing is carried out at a temperature of 35 °C for 2 hours. At the same time, the water is constantly changed, and the skins are rinsed by hand.

Soak. After washing, the skin is placed in a salty solution (20 g of salt per 1 liter of water) to soak. Soaking is carried out at a temperature of 35 °C for 14–16 hours.

Pickling. For pickling, the skin is placed in a solution (pickel) containing salt (60 g of salt per 1 liter of water) and acetic acid (12 g of vinegar per 1 liter of water) for approximately 10 hours. To determine the end of pickling, the skin is removed from the pickel, bent and squeezed with your fingers. If a characteristic white stripe forms, then the process can be considered complete. After pickling, the skin becomes soft and acquires the ability to stretch in all directions.

Layover. After pickling, the skins are laid out for 24 hours.

Tanning. To consolidate the effect obtained from pickling, the skins are tanned, during which they become resistant to moisture, heat and chemicals. The tanning operation is carried out with a commercially produced dry chrome tanning agent with a specified content of chromium oxide. The skins are placed in a solution prepared from tanning agent for 10 hours. If the tanning process is combined with fatliquoring, then ready-made fat paste is added to the solution at the rate of 15 g of paste per 1 liter of solution.

Fatliquoring. After tanning, the skins are fattened, for which they are again laid to rest for 6 hours, and then squeezed out and treated with a fat emulsion. The fatliquoring process makes the skin softer and more flexible. The composition of the fat emulsion includes water, fat, ammonia and laundry soap. To prepare the emulsion, laundry soap is dissolved in water (200 g of soap per 1 liter of water), the temperature of which should not be lower than 40 °C. Fat (80 g of fat per 1 liter of soap solution) and ammonia (10 g per 1 liter of solution) are added to the finished solution. The prepared fat emulsion is applied to the flesh with a brush, after which the skins are laid to rest for 6–8 hours.

Drying. After fatliquoring, the skins are dried at a temperature not exceeding 30 °C, then they are laid out again for 6 hours. After curing, the skins are straightened on a blunt braid and the fur is cleaned by combing and beating.

After performing the above operations, the skin is considered tanned.

Methods for accelerated skinning

Most nutria producers use accelerated methods for preparing skins. At the same time, the skins obtained after an accelerated processing operation are only slightly inferior in quality to skins processed in compliance with all the complex technological operations developed by specialists.

One of the most common methods for preparing nutria skins is the following. The skins, removed from the straightening and degreased using sawdust or a dry, clean cloth, are placed for 30 minutes in a solution prepared from any washing powder and warm water (35 °C) in the proportion of 3 tablespoons of powder per 20 liters of water.

After this time, the skins are thoroughly washed and placed in a solution consisting of table salt(400 g of salt per 1 liter of water), lactic acid (30 g of acid per 1 liter of water) and aluminum alum (10 g of alum per 1 liter of water). The solution temperature must be at least 18–20 °C. After a day, the skins are removed from the solution, washed again with a solution of washing powder and water, and then rinsed several times in warm water.

To dry, the skins are put on a hoop and hung indoors (in winter) or on fresh air, in the shade (in summer time). As the skins dry, they are stretched to give elasticity to the skin tissue. After drying, the inside of the skins is treated with emery until it becomes velvety.

There are other methods for processing nutria skins. Thus, some nutria growers use formaldehyde, sold in pharmacies, as a tanning agent. Before dressing, the skins are immersed in warm salt water, fat and muscle films are removed from the flesh, after which the skins are thoroughly washed in a soapy solution and rinsed.

After this, the skins are placed in a salty solution (30 g of table salt per 1 liter of water). After 30 minutes, add to the solution soda ash(1 g of soda per 1 liter of solution), and after another 30 minutes - formalin (4 ml of formalin per 1 liter of solution). The solution temperature should be maintained at 25 °C.

After 5–6 hours, sulfuric acid (5 g of acid per 1 liter of solution) or acetic acid (15 ml of acid per 1 liter of solution) used to prepare the electrolyte in batteries is poured into the solution. After 8 hours, ammonia is added to the solution (4 ml of alcohol per 1 liter of solution) and after 1 hour the tanning is completed.

The skins are removed from the solution, squeezed out and fattened with an emulsion consisting of laundry soap (50 g of soap per 1 liter of water), fat and machine oil. The solution is thoroughly mixed, ammonia is added (20 g of alcohol per 1 liter of solution and the resulting mixture is applied to the skin.

After fatliquoring, the skins are dried, kneaded, sanded with sandpaper, pounded, and then the fur is wiped with industrial alcohol.

The most in a fast way dressing of skins is next. Well-dried and cleaned raw materials are immersed in cold water soak for 12 hours, after which they are degreased by placing for 12–14 hours in a solution consisting of water, table salt (5 g of salt per 1 liter of water) and washing powder (6 g of powder per 1 liter of water). Then the skins are squeezed out and a second operation is carried out to remove the muscle film and fat on the flesh. Then the skins on both sides are thoroughly washed in a warm soapy solution and rinsed in clean cold water.

Pickling is carried out in a solution of 70% acetic acid (12 g of acid per 1 liter of water) with the addition of table salt (50 g of salt per 1 liter of water), in which the skins are kept for 20 hours. After pickling, the skins are pressed out and laid out for 30 hours, then the tanning process begins.

For tanning skins, use a solution of the following composition (per 10 liters of water): 50 g of table salt, 70 g of hyposulfate, 30 g of potassium alum. The skins are placed in the prepared solution for 12 hours. Then the raw materials are left to sit for 5 hours.

Next comes the fatliquoring process, in which the skins are pressed with the fur outward and an emulsion, which includes laundry soap and melted pork fat, is applied to the skin tissue with a brush. To prepare the emulsion, soap is dissolved in warm water (60 g of soap per 200 ml of water), after which melted pork fat is added (20 g per 200 ml of soap solution). The prepared emulsion is applied with a brush to the skin tissue of the skin. After fatliquoring, the skins are left to cure for 5–6 hours.

After fatliquoring and subsequent curing, the skins are dried at room temperature, fur side out, for 5 hours. Then the raw material is turned inside out. This process is called “tube drying”, and to facilitate it, many fur farmers use a bell-shaped device made of soft wire with a cross-section of 3 mm. A skin is put on the “bell” to dry. Moreover, the size of such devices may vary. Thus, for drying medium-sized skins, a “bell” with a height of 50 cm and a diameter of the lower ring of 12 cm is used; The diameter of the top ring should be about 8 cm.

Drying the skins on the “bell” lasts 10–12 hours, after which they are removed and dried in a suspended state. 2–3 hours before final drying, the raw materials are put on straighteners and stretched in length and width, smoothing out any irregularities.

After the skins have completely dried, they are kneaded. Moreover, the kneading process is carried out only manually and lasts until the leather tissue becomes soft. Then the fabric is sanded with sandpaper and all defects in the coat are removed.

Elimination of defects on dressed skins

Before you start sewing fur products, it is necessary to eliminate all defects on the dressed skins, which include holes, tears, “snacks” and bald spots.

To detect defects, the dressed skin is bent crosswise and blown onto the hairline, having first combed it with a metal comb, first in the direction of the hair, then in reverse side. Noticed defects are noted by piercing with the tip of a furrier's knife from the side of the hair without cutting it. Having made the pricks, the skin is placed on a horizontal surface with the wool down and we begin to eliminate defects.

To eliminate defects up to 1.5 cm wide, use longitudinal cutting (“fish”): using the pricks of a knife, cut out the damaged part of the skin in the shape of a fish, the length of which must necessarily exceed the width of the defect by more than 6 times (if this rule is not followed, then skin tissue after stitching the edges of the incisions, wrinkles will appear).

When eliminating defects, you should remember that the cut is made only in the longitudinal direction of the skin, and in no case in the transverse direction. After removing the defect, the edges of the incisions are pulled together so that they form a straight line, and then they are stitched over the edge.

If the defect width is more than 1.5 cm, the so-called wedge release is used. In this case, the existing defect is cut out in the form of a diamond, after which a wedge-shaped incision is made, the length of which must be at least three times the width of the defect. Next, the wedge is moved to the cut out part, and the gap formed after moving the wedge is stitched.

The commercial value of nutria skin is determined by the degree of hair development, color, size and strength of the skin tissue (hide). Therefore, the larger the nutria, the greater its value.

One of the most important features that determine the quality of nutria skins is the thickness of the hair. The durability, beauty and warmth of the skin depend on it. If there is a thick awn, the downy hair is completely covered on all parts of the body. The density of the down is determined by the width of the strip of skin that forms when the downy hair is pulled apart. When determining the grade of nutria skin, the main attention is paid to the thickness of the fur on the abdomen, as the most valuable part of the skin.

Hair density depends on the season of the year, the age of the nutria, the level of feeding, hereditary characteristics nutria. However, it has been established that even under equivalent feeding and housing conditions, hair density may vary in different individuals at the time of slaughter. These differences are primarily due to hereditary inclinations. Therefore, it is necessary to select nutria with thicker fur for the tribe, since this trait is mainly inherited.

First of all, a little about the structure of the skin tissue and hair of nutria. The skin of the nutria body consists of:

1) epidermis - the top layer of skin, consisting of integumentary epithelial cells that gradually die and are replaced by new ones;

2) dermis - a layer of skin tissue on which the epidermis lies. The strength of the skin depends on the degree of development and density of the dermis. The dermis is a relatively thick layer of connective tissue with 2 types of fibers - collagen (96-99%) and elastin (about 1.5%). Collagen fibers are located along the length of the body and only a small part is located in the transverse direction, and therefore the skin is more easily torn along than across.The strength and elasticity of collagen fibers depends on temperature regime drying and in order not to lose the strength of the skin, it is dried at a temperature no higher than +30 degrees.Elastin fibers form a kind of network, are able to contract when dry, and when re-moistened, they restore their original elasticity. This allows, if necessary, to further process the skin and correct its shape.

3) under the dermis there is a fatty layer with loose connective tissue, which must be removed during primary treatment so that it does not affect the quality of drying and the strength of the skin.

4) the lowest layer of leather tissue - muscular - is a thin film, which is removed during the initial processing of the skins.

Nutria skin contains sebaceous glands, which protect the skin from drying out and give the hair softness and shine. Nutria skin is thicker on the spine and thinner towards the abdomen.

Hair is a derivative of the skin and is located on it in groups, in one group, depending on age and season, from 20 to 130 units. According to their function and their shape, nutria hair is divided into guides, guard hairs, down hairs (93-98%) and vibrissae (with great sensitivity - on the lips, eyebrows, cheeks). The fur on the abdomen is 2.5 times thicker than on the ridge.

Changes in hair growth in nutria are caused by several factors. First of all, age-related variability, consisting of three periods:

1) embryonic, intrauterine, starting from 2 months of age, hair is formed gradually from the head, then on the back, abdomen, chest. The growth of primary hair continues after birth and is completed by 35-40 days of age (depositing time).

2) the formation of secondary hair occurs, the laying of which occurs almost immediately after birth. Secondary hair growth continues until 3-5 months of age. As the gut grows, primary hair gradually falls out, and secondary hair growth intensifies. Subsequently, until approximately 5 months of age, new hair grows, which compensates for the thinning of fur due to the intensive growth of the young. The process of primary hair loss (molting) ends by 110-120 days.

3) change from secondary to tertiary hair: the hair of an adult animal is thicker and longer. This period lasts from 150-165 days of age to 210 days, after which new hair growth occurs at a slower pace.

Seasonal hair loss (molting) has not been observed in nutrias; hair falls out and grows back imperceptibly throughout the year. Only with acclimatization of nutria in the northern regions did a slight decrease in molting in winter appear.

In different parts of the body, the commercial properties of hair and skin tissue are different. There is the concept of “topographic areas of the skin”: between the eyes, head, scruff, neck, shoulder, ridge, rump, side, chub, belly, thigh, paw, tail.

When assessing the commercial properties of nutria skin, first of all, the characteristics of the hair coat, its color, shine, height, evenness, fluffiness, softness, strength, and degree of felting are given.

Nutria skins are sorted according to GOST 2916-84 “Untreated nutria skins”. This standard applies to uncured cage-bred and hunted nutria skins.

Nutria skins must be removed from the carcasses using a “tube” with a cut along the rump and along the border of the hairless part of the paws and tail, preserving the head. The skins must be cleaned of meat, cartilage, tendons, blood from the skin and hair; degreased without damaging the hair roots; mounted on straighters without excessive stretching with a ratio of length to width of 3:1, preserved in a fresh-dry method and dried with the skin or hair facing out (skins coming from specialized fur farms must be dried with the hair facing out).

Nutria skins, depending on the color of the hair, are divided into color types:

Black skins should have black or almost black hair on the ridge, black to dark brown hair on the belly, and dark gray to dark brown down.

Brown skins should have ridge hair ranging from grayish brown to dark brown. The color of the hair on the skull is lighter than on the ridge. The guard hairs on the ridge and sides have a zonal coloration; the downy hairs are brown in color of varying intensity.

Pastel skins should have hair of a pure brown color of varying intensity, downy hair - from light brown to brown.

White skins - white hair.

Golden skins should have hair on the ridge ranging from orange to light yellow in color with a golden tint, hair on the womb should be lighter in color than on the ridge, downy hair should be yellow of varying intensity. Darker tops of downy hair are allowed.

Pearl skins should have a light brown to beige hair coat with lightened tops of the covering hairs. The color of the hair on the skull is lighter than on the ridge; the downy hair is from beige to almost white. A yellowish tint to the coverts and downy hair is allowed.

Depending on the quality of the hair, nutria skins are divided into varieties:

I grade - Full-haired, with a shiny awn, thick down and a well-furred belly

Grade II - Less full-haired, with insufficiently developed awns and down or less dense hair.

Depending on the presence of defects, nutria skins are divided into defect groups in accordance with the requirements specified in table. 3.

Table 3 - Defect groups for nutria skins

|

Name of the vice |

||||

|

fourth |

||||

|

Tears and seams total length, cm |

>25.0 up to one times the length of the skin; skins torn across or with a cut along the ridge line |

|||

|

Holes, worn out places, sections of the v.p., spots of a different color (pejins) with a total area, cm2 |

||||

|

Draft, piled-up snacks, matted hair with total area, cm2 |

||||

|

Bald spots with total area, cm2 |

||||

|

Missing skin parts |

Cut out the lower part of the womb up to 5.1 cm from the line between the side points of the rump |

Heads. The cut out lower part of the womb is 5.1 - 10.0 cm from the line between the side points of the rump |

Heads with necks |

Notes:

1. Skins with pezhins on the head, with overgrown or single not overgrown bites, with defects on the lower edge of the womb up to 5.1 cm, with a cut along the midline of the womb are classified in the “first” group.

2. Defects on the head and neck are valued no higher than the discounts established for the shortage of these parts of the skin.

3. For different defects located on the same area of the skin (flaw on defect), one largest defect is taken into account.

Table 4 - Assessment of the quality of nutria skins in percentage

|

Defect group |

||||

|

fourth |

||||

Poorly defatted nutria skins are accepted with a 10% discount on the quality assessment of the skins.

Nutria skins with defects exceeding the tolerances for the “fourth” group, skins with a cut out belly more than 10 cm from the line between the side points of the rump are assessed no higher than 25% of the quality assessment of skins of the corresponding color, first grade and first group. The skins are rotten, burnt, damaged by moths and skin beetles, with very sparse hair, half-haired, skins of cubs with plump hair are classified as non-standard.

Characteristics of defects

The quality of skins depends not only on their natural, natural properties, but also from various damage to their hair and skin tissue. All these defects reduce the value of harvested fur raw materials, complicate its processing, and deteriorate the quality of manufactured products.

There are intravital defects - those that arose on the skin during the life of the animal, and post-mortem defects - those formed during the extraction of the animal, or during the initial processing, storage and transportation of skins.

Lifetime vices:

A wiped area is an area of the skin with partially or completely destroyed hair due to mechanical damage.

A bite is an area of skin with damage to the skin tissue and hair due to a bite.

Spots of a different color (pezhina) are a section of the skin that has a clearly defined hair color that contrasts with the main one.

Hair matting is the tangling of hair to the point of forming a felt-like mass that cannot be combed.

Sectioned hair is a break in the tops of the covering hairs.

Posthumous defects:

Tears are linear holes in the leather tissue of the skins without loss of its area, usually occurring when the leather tissue is under strong tension when removing and editing the skins.

Hole - an opening in the leather weave with loss of area.

A bald spot is an area of skin with completely lost hair due to the action of microorganisms on the skin tissue.

Draft - exposure of hair roots from the skin tissue. This occurs during unskilled degreasing of the skin, when a sharp, deep-cutting tool is used, thereby exposing the roots of the hair, cutting off their bulbs.

One of the reasons for the appearance of such defects as loose hair, prelines, bald spots is a violation of the drying regime of raw materials, especially on wire-type rules, in conditions when the relative air humidity is 20-40%, and the temperature rises to 40-500. At the same time, the surface of the leather fabric dries out greatly, while the inner layers remain wet. The optimal temperature for drying nutria skins can be considered to be 27-300C, relative air humidity - 55-60%. At high temperatures The possibility of collagen welding or keratinization cannot be ruled out either.

By improving the methods of shooting, degreasing, straightening, and drying skins, their quality can be significantly improved.